Explorer

The Explorer series is a cost-effective coordinate measuring machine (CMM) divided into two models: Explorer Classic and Explorer Performance. The Explorer Classic supports universal touch-trigger measurement, meeting the requirements of various parts. For more demanding applications, the Explorer Performance can support continuous scanning function with higher accuracy and better performance. The frame embeds some of the technical characteristics of higher-end products in the Hexagon bridge CMM range, ensuring optimal performance in terms of accuracy, reliability and dynamics. The CMM range features a low cost of ownership and is an affordable measurement solution.

GLOBAL Advantage ( CMM )

FEATURES

When purchasing a coordinate measuring machine, manufacturers need to be confident that their system will last for the long term. The all-aluminium ultra-rigid frame of the GLOBAL Advantage provides optimum stiff-to-mass ratio for unquestioned precision and long-term stability.

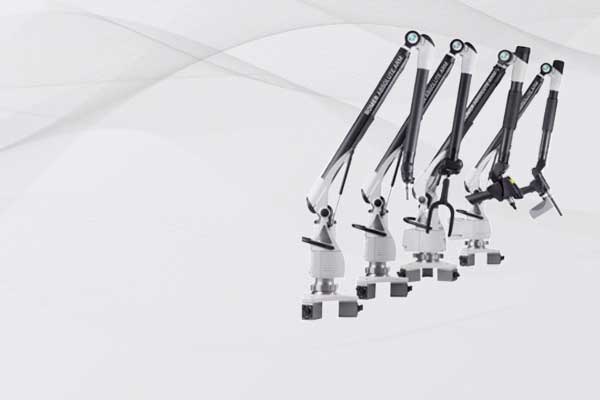

▶ Versatile Sensor Configuration

When creating an inspection plan for parts varying in complexity, feature characteristics and material types, manufacturers require a solution that is both precise and versatile. The GLOBAL Advantage CMM supports multisensor technology in a variety of configurations to suit different material types and feature characteristics. Whether you are looking for a more precise fixed probe head such as the HP-S-X5-HD or use an indexable probe head such as the HH-A 2.5 HD to reach more positions on the part, the GLOBAL Advantage can efficiently address the challenges. For even more access to hard-to-reach features, both probe head configurations are compatible with extension probes ranging from 750 mm up to 800 mm.

▶ Integration-Ready

Purchasing a CMM is an investment and manufacturers need to be prepared for the future. The GLOBAL Advantage CMM is accessible from four sides to ensure easy integrability with part loading/unloading systems. Furthermore, the system can be integrated with an automated loading/unloading system or supplied with specific fixturing, ensuring you are prepared for what lies ahead.

▶ Take the PULSE of Your Environment

Running part programs on large complex components take time. Having control of the environment surrounding your CMM during the entire measurement cycle is essential to obtain accurate measurement results the first time, every time. With added protection from pollution and dust, advanced temperature compensation algorithms and an optional environmental monitoring system, the GLOBAL Advantage CMM gives manufacturers confidence that their system is in optimal performance.

▶ Use Software to Embed Quality Across the Organisation

The right metrology software gives manufacturers the tools necessary to easily create and execute measurement routines and communicate the results quickly and effectively. PC-DMIS has over 20 years of built-in expertise enabling manufacturers to capture and share quality information seamlessly across the organisation and through all phases of production. For more demanding applications such as the inspection of special or complex geometries or challenging data evaluation, the powerful QUINDOS software with its range of specialised modules offers the sophistication required by the most advanced metrology user.

GLOBAL Classic ( CMM )

▶ GLOBAL Classic is a cost-effective solution for dimensional quality control. This CMM is equipped in its standard configuration with touch-trigger probes. Scanning probes are also available as an option. GLOBAL Classic offers the best price/performance ratio throughout the entire GLOBAL family.

▶ The scanning version also benefits from the throughput improvements that characterise the GLOBAL line. The optional CLIMA structural temperature compensation ensures good accuracy in a wide temperature range.

TECHNICAL DATA

| Measuring Range (in mm) | ||

| X | Y | Z |

| 500 | 500 – 700 | 500 |

| 700 | 700 – 1000 | 500 – 660 |

| 900 | 1200 – 1500 – 2000 | 800 |

| Accuracy: MPEE = from 1.9 + L/300 μm | ||

GLOBAL S Series

The GLOBAL S Series coordinate measuring machine (CMM) delivers measurement productivity tailored to your workflow, addressing the widest range of production requirements including throughput, precision, multi-purpose and shop-floor capabilities.

With productivity being the key competitive driver in manufacturing, it’s crucial that the measurement process provides the data required for the application and fits seamlessly into the production workflow and cycle times. The GLOBAL S coordinate measuring machine (CMM) provides superior measurement performance and enhanced productivity for your specific production needs.

Designed by Pininfarina and powered by the Hexagon Manufacturing Intelligence Enhanced Productivity Series (EPS) concept, GLOBAL S combines smart technologies including user experience enhancements, advanced software and eco-friendly options to provide measurement solutions with three performance levels: Green, Blue and Chrome, to suit the requirements of your application. EPS machines allow you to select your main productivity driver: throughput, precision, flexibility or shop-floor measurement, and configure the machine with the best capability package for that driver. GLOBAL S can also be fully-customised to suit the most challenging production environments.

Through a highly-configurable technology platform, GLOBAL S ensures that quality engineers creating measurement routines, operators executing the inspection, and quality managers analysing the data all have the solution needed to ensure continuous improvement in the production workflow.

TIGO SF ( CMM )

▶ Open Access Measuring Volume

Easy loading and unloading of workpieces thanks to the full accessibility offered by the TIGO SF’s three open sides.

▶ Compact Size

The PC, controller and peripherals including the screen and the keyboard are all mounted to the same base to ensure minimal footprint for easy placement onto the shop floor or production line. TIGO SF offers the best volume to footprint ratio in its class.

▶ Linear Guideways

All axes on the TIGO SF work on a linear guideway system with no air required, reducing the risk from production contaminants and making installation and relocation simpler.

▶ Ergonomic Workstation

TIGO SF’s ergonomically-designed workstation allows operators to position the screen and keyboard exactly where they need it, while an easy-to-reach USB port enables fast data transfer.

▶ Eco Mode

Eco Mode automatically powers down the machine when it stands idle, improving energy efficiency without shutting down the CMM. Eco Mode supports environmental sustainability whilst reducing operating costs, giving metrology the green light.

▶ Fly2 Mode

Fly2 Mode is a trajectory-control feature for enhanced probe movement. It decreases program execution times whilst reducing operating and maintenance costs by optimising machine motion and trajectories, causing less stress on moving parts.

▶ Scan Pilot

The Scan Pilot advanced firmware algorithm and motion-control parameters enable accurate measurement of undefined path profiles quickly with minimal setup. Consistent contact is achieved through greater motion control, even in the presence of abrupt surface changes, allowing users to save time on non-predefined measurement tasks.

▶ PULSE

When fluctuations in environmental conditions are enough to affect a measurement result, PULSE provides traceability through environment monitoring. PULSE uses a network of sensors to record variations in temperature, vibration and humidity in the CMM environment as well as monitoring for machine collisions, and sends alerts to the user via email or SMS when predefined operating conditions are exceeded.

▶ XT Option

The optional XT upgrade enables accurate and reliable measurement in an expanded temperature range of 15 °C to 40 °C, and can be applied to all new TIGO SF CMMs or to existing machine installations as a retrofit.

▶ Messaging Lights

LED status indicator lights are mounted on the Z-axis cover to allow at-a-glance assessment of the machine and program status from across the factory floor. Users have a clear visual indication of whether measurements are in progress or if the CMM requires operator intervention. This means the CMM can be left unattended, allowing time and resource optimisation.

TECHNICAL DATA

| Measuring Range (in mm) | ||

| X | Y | Z |

| 500 | 580 | 500 |