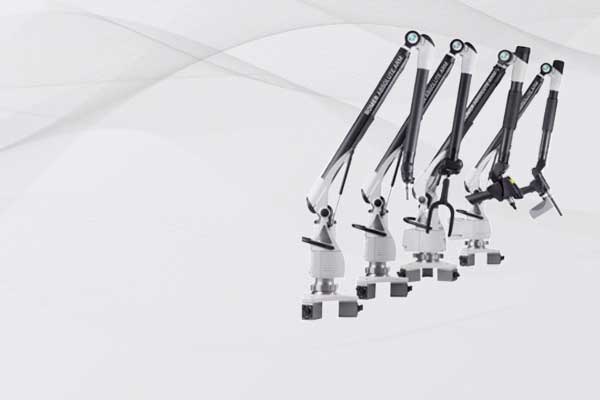

PhaseII PHT-6000 SERIES

Ultrasonic Portable Hardness Tester

UCI/Dynamic Hardness Tester

Series 6000

Features:

▶ Non-Destructive hand held portable hardness tester

▶ Combines UCI and Leeb portable hardness testing in one state of the art device

▶ Test steel with min thickness of .08” and unlimited max thickness (Other materials may have larger minimum thickness levels, depending on hardness)|

▶ Blazing fast test results

▶ Rockwell, Brinell and Vickers hardness test conversions shown on display

▶ Large Memory w/USB Output

▶ Choice of manual UCI probes; 1kg, 2kg, 5kg & 10kg

▶ Optional Motorized Probes: .30kg, .80kg, & 1kgf

▶ Available Impact Devices(Leeb) D, DC, D+15, G & DL

PhaseII PTG-3700 SERIES

COATING THICKNESS GAUGES /

PAINT THICKNESS GAUGES

PTG-3700 SERIES

Technical Data

▶ Measuring Range: 0-1250um or 0-50mils

▶ Resolution: 0.1um to 100um, 1um over 100um

▶ Accuracy: +/-1-3%N or 2.0um, whichever is greater

▶ Min measuring area: .2” x .2” (5mm x 5mm)

▶ Min substrate thickness: ferrous 20 mils(.5mm), Non-ferrous 2mils(50um)

▶ Min radius of curvature: Convex .12” (3mm), Concave 1.2” (30mm)

▶ Max surface temp: 302 deg F (2 second contact)

▶ Power: 2 AAA

▶ Dimensions: 126 x 65 x 35mm (5 x 2.6” x 1.5”)

PhaseII PTG-4000 SERIES

PTG-4000

COATING THICKNESS GAUGES

Technical Data

▶ Measuring range: 0-1,250 µm max. or 0-50 mils

▶ Resolution: 1 µm / 0.1mils

▶ Accuracy: +/- 3% + 2 µm ( +/-3%+0.1 mil )

▶ Display: 3 digit color LCD

▶ Statistics: Min/Max, Average, Std Deviation

▶ Single or Continuous Measurement(Selectable)

▶ Min. measuring area: 0.2″ x 0.2″ (5mm x 5mm)

▶ Min. radius of curvature: Convex: 0.12″ (3mm) Concave: 1.2″ (30mm)

▶ Min. substrate thickness: Ferrous: 20 mils (0.5mm) Non-ferrous: 2 mils (50 µm)

▶ Max. Surface temperature of test object: 302 degrees F (contact time max is 2 seconds)

▶ Power source: 2-AAA batteries

▶ Dimensions: 100 x 52 x 29mm

▶ Weight: 2.4oz. (w/o Batteries)